What’s new in Siemens NX for manufacturing (June 2025) – Siemens NX Design Blog

The latest release of NX for Manufacturing is here, bringing a set of powerful enhancements that make part production easier and more efficient.

From introducing a new product tier in NX X Manufacturing, to smarter automation in NX CAM that reduces programming time, improved additive capabilities for consistent prints, enhanced on-machine probing and inspection for greater accuracy, and stronger data management to support collaboration and traceability, this release brings important improvements across the board.

Let’s take a closer look at what’s new in NX 2506.

What’s new in NX X Manufacturing

NX now offers a cloud-based software-as-a-service solution with NX X Manufacturing. Since launch, it has changed how part manufacturers collaborate, manage, and access software in a cost-effective way.

NX X Manufacturing is simple to deploy and install on your devices, with flexible access – either offline on a desktop or streamed remotely, depending on your needs.

With software updates and infrastructure taken care of, manufacturers like you can focus on what matters most: making high-quality parts and bringing them to market faster.

NX X Manufacturing Essentials

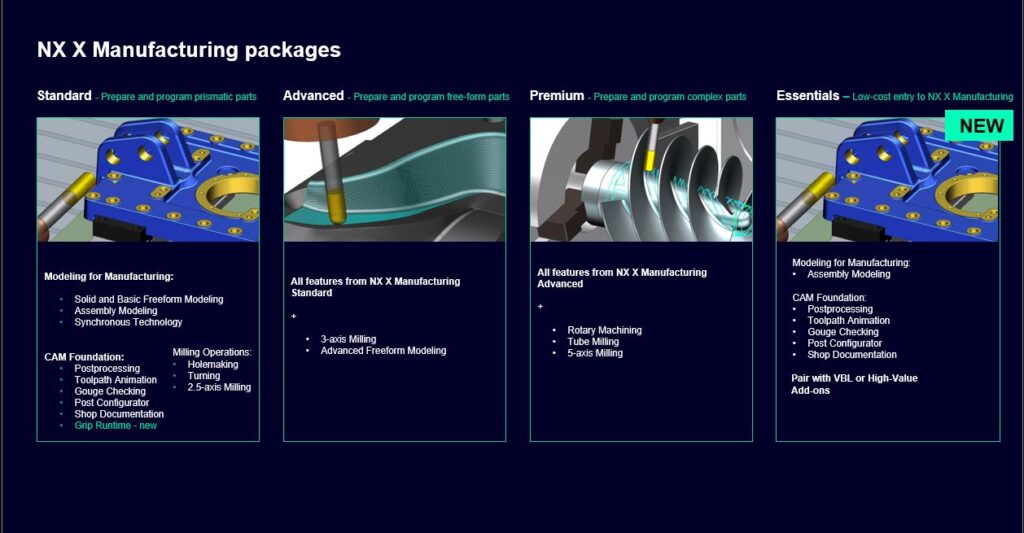

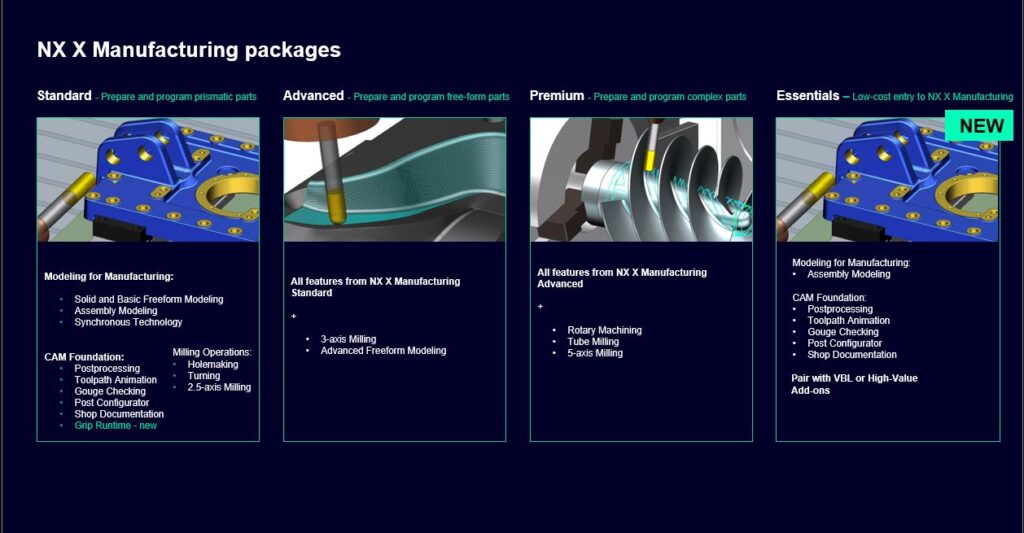

NX X Manufacturing now offers four product tiers – Essentials, Standard, Premium, and Advanced – with the flexibility to expand capabilities through floating NX X Manufacturing Value-Based Licensing Add-ons.

With the latest release, a new base tier has been introduced: NX X Manufacturing Essentials. You can view and interact with 3D part models and manufacturing data directly within the NX X Manufacturing environment—making it a cost-effective way to get started.

NX X Manufacturing Essentials includes:

- Built-in data management: Manage versions and revisions of machining, control access to NC programs and collaborate confidently with a single source of truth

- Manufacturing visualization: review setups, operations and toolpaths and provide feedback to authors of NX and CMM programs, as well as 3D printing building jobs

- Postprocessing and shop documentation: generate production-ready G-code with the use of a versatile postpocreesor and access cloud-based library of over 1,000 postprocessors

NX X Manufacturing Essentials can be paired with Value-Based Licensing and High-Value Add-ons, such as NX X Line Designer and NX X Assembly Line Planner, to expand its functionality.

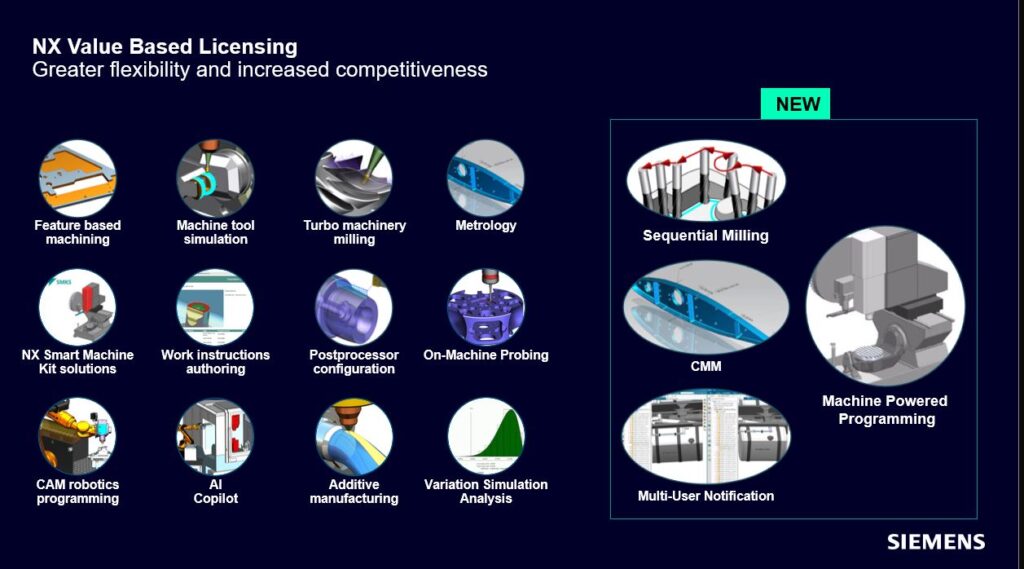

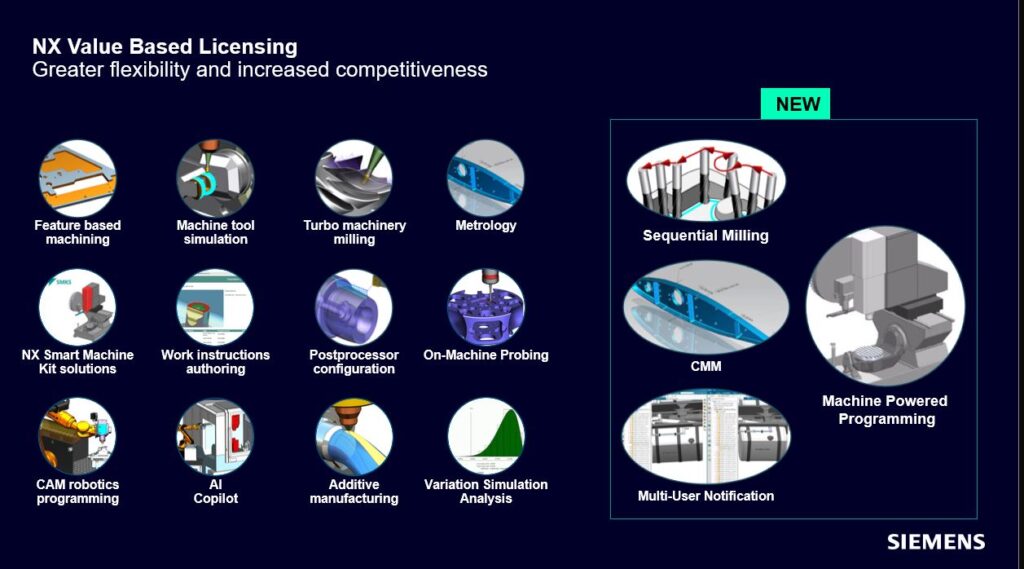

With NX X Manufacturing Value-Based Licensing, you get a flexible, cost-effective way to access more than 20 specialized add-ons using value units (credits), so you only pay for what you use, instead of buying fixed modules.

You can customize your solution with key add-ons such as productivity tools, advanced machining capabilities, G-code-driven simulation, postprocessors, machine kits, and advanced CAD tools. We’ve now expanded the list with new options including on-machine probing, sequential milling, CMM inspection, machine-powered programming, and multi-user notifications.

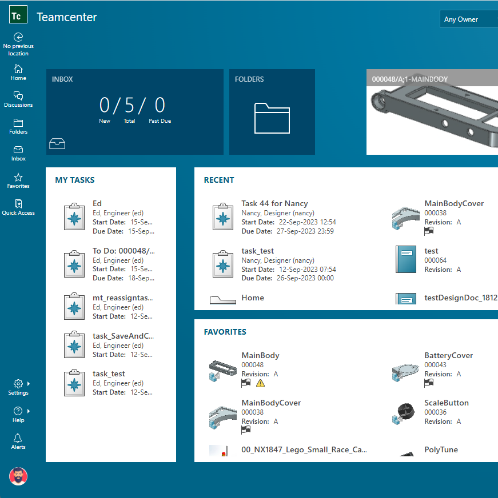

Built-in data management

Managing complex CAM data can be challenging, especially when multiple design parts, machining operations, and stakeholders are involved. That’s why the latest release of NX X Manufacturing also introduces built-in data management as a major feature, delivering essential product data management capabilities for users. NX X Manufacturing Built-in Data Management (BIDM) is built to handle the complexity of modern manufacturing while keeping your data accurate, connected, and accessible.

Built-in data management supports controlled collaboration by centralizing the storage, sharing, and versioning of manufacturing data. It ensures data consistency, improves traceability of part programs and process plans, and minimizes errors from outdated information. While not a full-scale PLM replacement, it offers a practical solution for smaller teams or those seeking greater data control within NX X Manufacturing.

Aligned with NX’s open architecture, it provides flexibility and choice, allowing users to adopt the data management approach that best fits their needs.

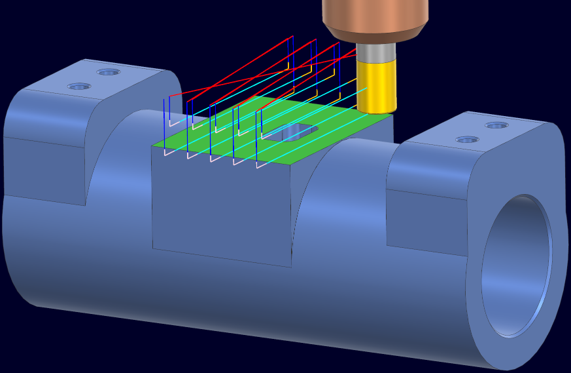

What’s new in NX CAM

New enhancements in NX CAM focus on automation and intelligent, machine-powered programming, enabling faster workflows, improved accuracy, and better part quality.

App Hub

App Hub, a cloud-based marketplace for modular and third-party applications, such as (mention a couple of the apps). With one click, users can install the apps and stay current with the latest NX CAM features.

App Hub is fully integrated into the CAM environment and accessible through the CAM Applications ribbon bar, allowing users to browse, download, and launch apps without leaving NX or opening a browser—ensuring a smooth, single-workspace experience.

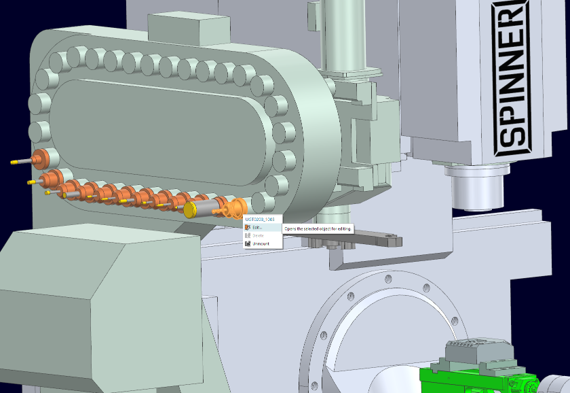

Graphical Tool Interaction

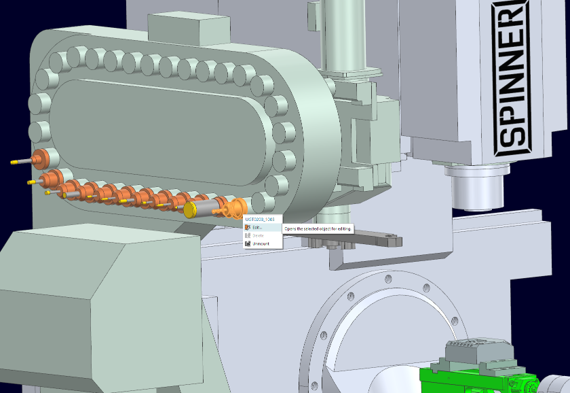

Tool commissioning process has been simplified with the introduction of direct graphical tool interaction in NX. Instead of navigating complex lists in Operation Navigator or Machine Setup Configurator, simply click on visible tools to display names, delete, or relocate them.

This intuitive approach eliminates the frustration of searching through cluttered interfaces, making tool commissioning faster and more efficient. Complex setups with multiple tools and carriers are now easier to manage through straightforward visual interaction.

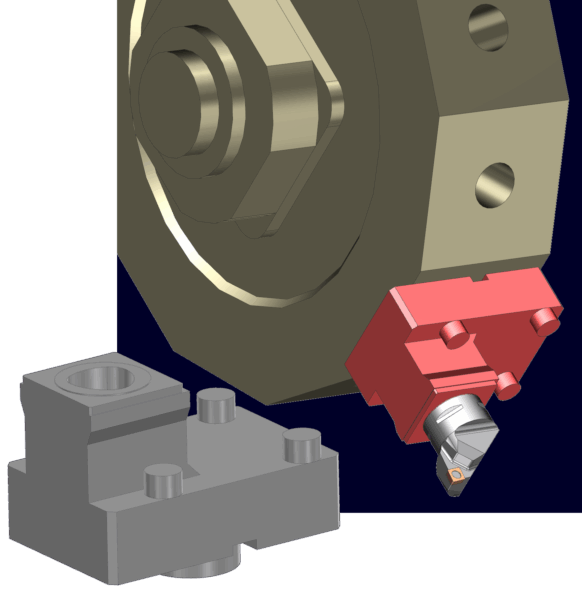

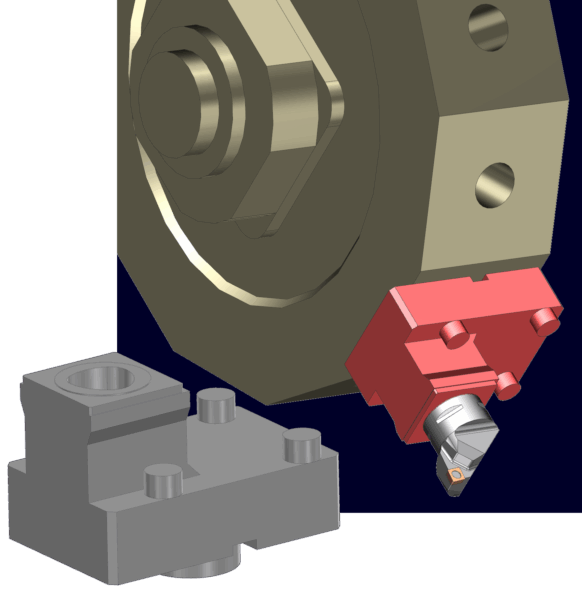

Tool Holder Support

We’ve upgraded tool holder management in the latest NX CAM to make it clearer and easier to use. Instead of the old _DEVICE or _HEAD labels that weren’t very specific, you’ll now see a straightforward TOOL_HOLDER classification for your changeable heads, turn tool holders, and drill holders.

Best part? Once you set up your tools and holders, they stay exactly as you configured them throughout your CAM programming. No more unexpected changes during machining, what you set is what you get.

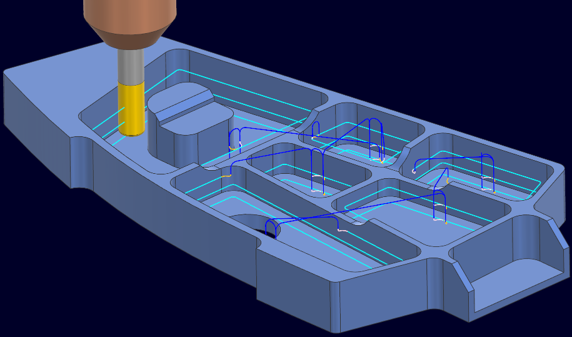

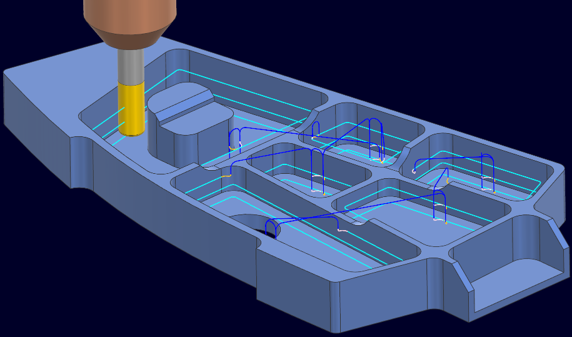

2D Wall Milling

The new 2D Wall Profiling is all about speed and simplicity. We’ve cleaned up the interface to show you just what you need – no more digging through complex menus. As you adjust your settings, you’ll see your toolpath update right away on screen.

You can use any tool you need – Flat, Chamfer, or Ball Mill – and easily set up your part, wall, and avoidance geometries. Want to machine the whole wall or just a section? Just set your range and you’re good to go.

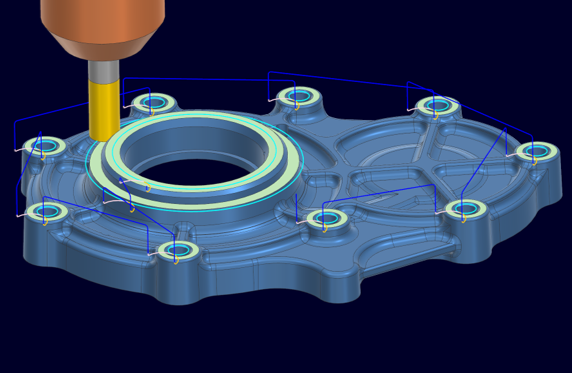

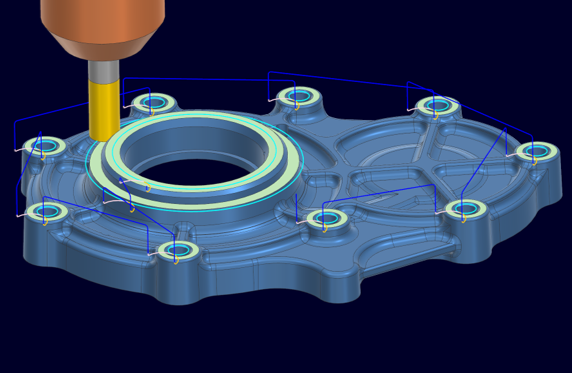

2D Face Mill Midpass – Support Multiple Faces

If you were spending time creating separate operations for each face while face milling, that’s no longer necessary. Face Mill Mid-Pass now handles multiple faces in a single operation – just select all the faces you need and organize them exactly how you want.

You have complete control over the machining order or let NX optimize the toolpath automatically. When faces are close together, the new Merge Distance feature creates smooth transitions between them in a single pass.

This means less time setting up operations and better toolpaths, especially when you’re working with complex surfaces. Simple, efficient and more flexible – exactly what you need for face milling multiple surfaces.

Machine Powered Programming

We’ve taken machine programming to a whole new level. It’s simple: NX CAM now does the heavy lifting for you, cutting your programming clicks in half while making smarter decisions.

Think of it as having a built-in expert that knows your machine inside out. It automatically sets up operations based on your part design and machine capabilities. No more manual tweaking of every parameter, the system figures out the optimal settings on its own.

New to CAM? No problem. Experienced programmer? Even better. It guides you with smart, context-aware prompts exactly when you need them.

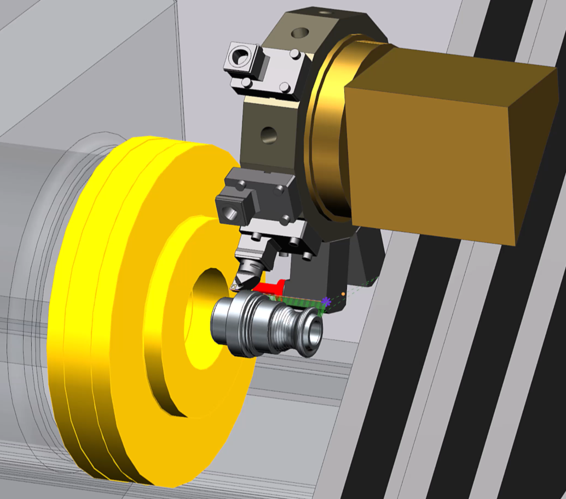

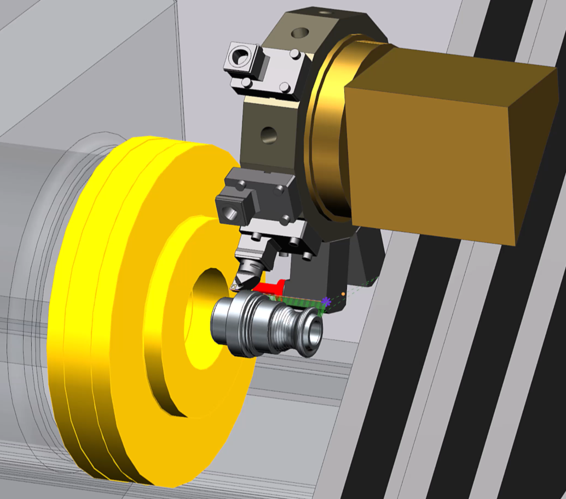

Check Tool Path for Machine Collisions

Machine-powered programming now delivers both visual verification and automated collision checking, ensuring safer, more efficient machining processes. The Display Tool in Machine feature provides real-time visual previews of machine state during programming.

But we’ve taken safety further with Check Tool Path for Machine Collisions – a system that automatically catches even hidden collision risks.

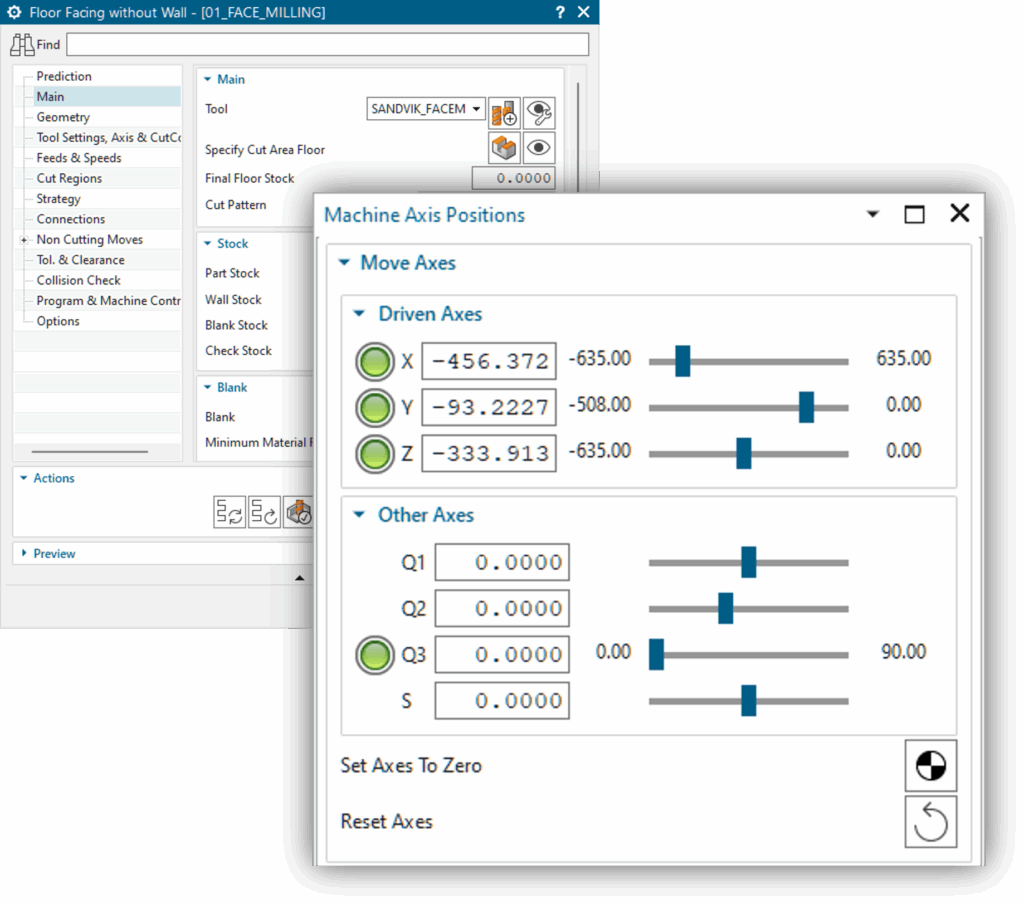

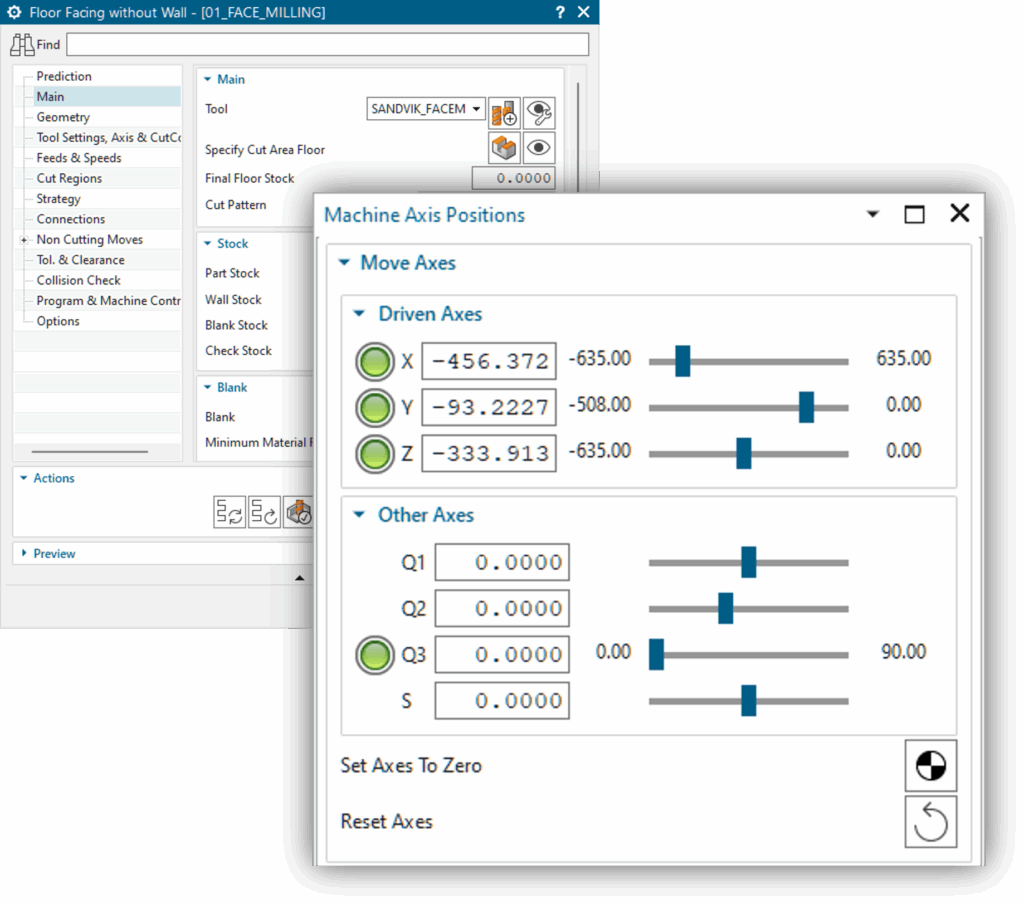

Display Machine Axis values during CAM Programming

Real-time feedback shows you exactly what’s happening with your mill-turn scenarios. Make decisions faster, validate your work instantly, and let NX predict and prevent issues before they happen.

The new machine axis dialog features intuitive sliders and manual inputs, letting you fine-tune positions in real-time – even while editing tools or refining operations. Dynamic toolpath animation displays live machine movements, with instant axis position updates and automatic limit violation alerts to prevent errors. This real-time control and visualization give you greater command over machine operations and toolpath precision.

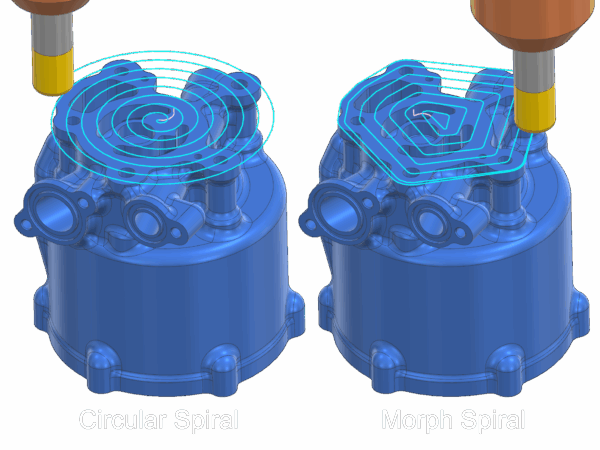

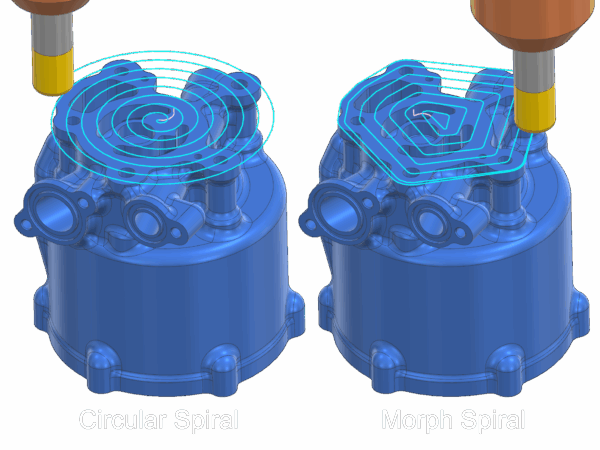

Facing Spiral

Spiral face milling gets a powerful upgrade in the latest NX CAM. With real-time visual feedback, you can instantly see how parameter adjustments affect your toolpath – from overhang to floor thickness and start points, ensuring error-free programming.

This new operation supports both circular and morph spiral patterns, delivering smoother cuts across planar faces while keeping all traditional face milling features. You’ll achieve more consistent surface finish with optimized machining.

We’ve streamlined everything with a modern interface and faster toolpath generation, making complex face milling as simple as adjusting a few controls. Whether you’re working on flat surfaces or complex geometries, you’ll get better results in less time.

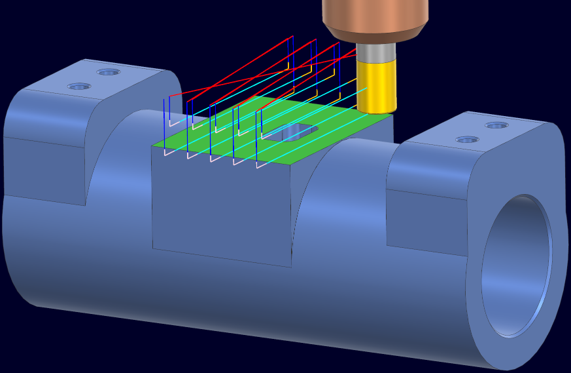

Facing Zig Zag – Contain path to specified machining surface

We’ve made toolpath containment a lot smarter, especially for those tricky castings and irregular stock pieces. Here’s the deal: NX now only cuts where you actually have material above your machining surface – not just anywhere it spots extra material.

In the past, if NX found any excess material within your cutting height, it would create a toolpath there, even if it was nowhere near where you wanted to machine. Now it’s much more focused – if there’s material off to the side or not connected to your machining surface, NX just ignores it.

Learn More

Explore NX’s advanced capabilities for NC programming by signing up for the NX X Manufacturing trial. No installation is required meaning you can run NX in your browser, in just a few minutes.

Eager to learn more about the NX for manufacturing features? Check out the step-by-step tutorial videos on our online community.

Zobacz również: What’s new in Siemens NX 2506 (June 2025)

Źródła: Siemens, Siemens